About

Serving Customers in America, Canada, Mexico and Europe

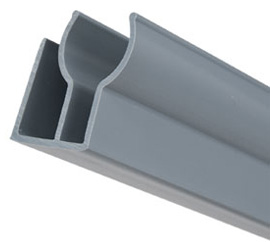

Established in 1986, ACE, Absolute Custom Extrusions is an ISO 9001:2015 certified custom extruder specializing in plastic tubing, profiles and coated wire & cable for the industrial and consumer markets.

From pre-prototype to post-production, we have the capability and experience to do it all...

Capabilities

- Serving Companies Large and Small

- Customers in America, Canada, Mexico and Europe

- We Sell to OEMs and Distribution Channels

- Handling Tough Material Requirements and Precision Tolerances

- Providing Prompt and Personal Customer Service

- Design & Engineering Assistance

We stock a broad variety of production-ready materials in our warehouse, so that we can be responsive to a full spectrum of production requirements.

ACE, Absolute Custom Extrusions is a woman owned small business that has grown because of its dedication to quality and attention to customer service.

Made in the U.S.A.

At Absolute Custom Extrusions (ACE), we proudly manufacture all our custom plastic extrusions in our ISO 9001:2015-certified facility in Milwaukee, Wisconsin, embodying the "Made in the USA" ethos. This commitment ensures that every product, from precision tubing to complex profiles, meets stringent American quality standards, delivering unmatched reliability for industries like defense, medical, and industrial manufacturing. By producing domestically, we maintain tight control over every stage of the extrusion process, using state-of-the-art equipment and a skilled workforce to achieve tolerances as fine as ±0.005 inches. Our "Made in the USA" status guarantees high-quality materials, such as FDA-approved polymers and high-performance plastics, tailored to meet specific customer needs, ensuring durability and performance in demanding applications.

At Absolute Custom Extrusions (ACE), we proudly manufacture all our custom plastic extrusions in our ISO 9001:2015-certified facility in Milwaukee, Wisconsin, embodying the "Made in the USA" ethos. This commitment ensures that every product, from precision tubing to complex profiles, meets stringent American quality standards, delivering unmatched reliability for industries like defense, medical, and industrial manufacturing. By producing domestically, we maintain tight control over every stage of the extrusion process, using state-of-the-art equipment and a skilled workforce to achieve tolerances as fine as ±0.005 inches. Our "Made in the USA" status guarantees high-quality materials, such as FDA-approved polymers and high-performance plastics, tailored to meet specific customer needs, ensuring durability and performance in demanding applications.

Choosing ACE’s American-made extrusions benefits our customers through faster lead times, enhanced supply chain reliability, and a commitment to sustainability. Domestic production eliminates the delays and uncertainties of overseas shipping, with our efficient processes enabling rapid quotations and delivery. By sourcing materials locally and recycling where possible, we reduce environmental impact while supporting the U.S. economy and local jobs. Our hands-on approach, from design collaboration to secondary operations like precision cutting and printing, ensures custom solutions that align perfectly with your specifications. At ACE, "Made in the USA" means delivering superior quality, responsiveness, and value to every customer, every time.

Absolute Custom Extrusions, Inc. - The Premier Supplier of Water Treatment Tubing

In the realm of water treatment, where precision, durability, and compliance with stringent standards are paramount, Absolute Custom Extrusions, Inc. (ACE) stands out as a leading manufacturer of custom plastic tubing tailored to meet the unique demands. With over 35 years of experience, a commitment to innovation, and a customer-centric approach, ACE has solidified its reputation as a superior supplier of water treatment tubing.

A Legacy of Excellence in Plastic Extrusion

Founded in 1986 and based in Milwaukee, Wisconsin, Absolute Custom Extrusions, Inc. is a woman-owned small business that has built a legacy of excellence in custom plastic extrusion. With an ISO 9001:2015 certification, ACE demonstrates its dedication to maintaining the highest quality standards in every facet of its operations. The company specializes in producing custom plastic tubing, profiles, and coated wire and cable, serving industries across the United States, Canada, Mexico, and Europe. Our expertise in water treatment tubing is particularly noteworthy, as they deliver solutions that meet the rigorous demands of water purification, filtration, and distribution systems.

ACE’s extensive experience in the plastic extrusion industry—spanning over three decades—has equipped them with the technical know-how and innovative capabilities to address the complex needs of water treatment applications. From municipal water treatment facilities to industrial purification systems, ACE’s tubing solutions are engineered to perform under challenging conditions, ensuring reliability, safety, and efficiency.

Why Water Treatment Tubing Matters

Water treatment tubing plays a critical role in ensuring the safe and efficient delivery of clean water. Whether it’s for filtration systems, reverse osmosis units, or chemical dosing applications, tubing must withstand exposure to harsh chemicals, high pressures, and varying temperatures while maintaining structural integrity and compliance with regulatory standards. The tubing must also be non-toxic, resistant to corrosion, and capable of maintaining tight tolerances to ensure seamless integration into complex water treatment systems.

ACE recognizes these challenges and has developed a comprehensive approach to designing and manufacturing water treatment tubing that meets and exceeds industry expectations. Our ability to deliver customized solutions tailored to specific applications sets them apart from competitors, making them a trusted partner for water treatment professionals worldwide.

Key Strengths of ACE’s Water Treatment Tubing

1. Customization to Meet Exact Specifications

One of ACE’s defining strengths is its ability to produce custom plastic tubing tailored to the precise needs of water treatment applications. Unlike off-the-shelf tubing, which may not meet the specific requirements of a given system, ACE collaborates closely with clients to design tubing that aligns with their unique specifications. This includes:

One of ACE’s defining strengths is its ability to produce custom plastic tubing tailored to the precise needs of water treatment applications. Unlike off-the-shelf tubing, which may not meet the specific requirements of a given system, ACE collaborates closely with clients to design tubing that aligns with their unique specifications. This includes:

- Dimensional Precision: ACE can engineer tubing with wall thicknesses ranging from 0.005” to 0.250” and outside diameters from 1/32” to 4”. This flexibility ensures compatibility with a wide range of water treatment systems, from small-scale residential units to large industrial setups.

- Material Selection: ACE offers a variety of high-performance thermoplastic materials, including polystyrene, acrylonitrile butadiene styrene (ABS), polypropylene, and recycled materials. These materials are selected based on the specific requirements of the application, such as chemical resistance, durability, and compliance with FDA standards for potable water systems.

- Custom Profiles: Beyond standard round tubing, ACE can produce complex profiles and shapes, such as multi-lumen tubing or co-extrusions with multiple layers, to meet the unique demands of water treatment equipment.

This level of customization ensures that ACE’s tubing integrates seamlessly into clients’ systems, reducing the risk of leaks, failures, or inefficiencies.

2. Uncompromising Quality and Compliance

Quality is at the core of ACE’s operations, and our water treatment tubing is no exception. As an ISO 9001:2015-certified company, ACE adheres to rigorous quality control processes to ensure that every product meets or exceeds customer expectations. Our tubing is thoroughly inspected to verify dimensional accuracy, material integrity, and performance under real-world conditions.

For water treatment applications, compliance with regulatory standards is non-negotiable. ACE’s tubing is designed to meet FDA standards for non-toxic materials, ensuring it is safe for use in potable water systems. Additionally, our products are resistant to chemicals commonly used in water treatment processes, such as chlorine, ozone, and other disinfectants, ensuring long-term reliability and safety.

ACE’s commitment to quality extends to our use of advanced manufacturing technologies, such as modern electrical discharge machining (EDM) for tooling, which enhances the precision and cost-effectiveness of our products. This focus on quality ensures that water treatment professionals can rely on ACE’s tubing to perform consistently in demanding environments.

3. Innovative Design and Engineering Support

ACE’s engineering team is a cornerstone of our success in the water treatment industry. With decades of experience, our skilled engineers work closely with clients to provide end-to-end solutions, from pre-prototype design to post-production support. This collaborative approach allows ACE to address the unique challenges of water treatment applications, such as:

- Material Optimization: ACE’s engineers assist clients in selecting the best materials for our specific needs, considering factors like chemical exposure, pressure requirements, and environmental conditions.

- Prototyping and Testing: Before full-scale production, ACE creates prototypes to ensure the tubing meets the client’s specifications. This iterative process helps identify and resolve potential issues early, reducing costs and lead times.

- Tooling Expertise: ACE has access to state-of-the-art tool and die resources, enabling them to create sophisticated, streamlined dies that produce tubing with exceptional precision. Our use of EDM technology further enhances tool quality, ensuring consistent performance across large production runs.

This hands-on approach to design and engineering makes ACE a valuable partner for water treatment companies seeking innovative and reliable tubing solutions.

4. Sustainability and Environmental Responsibility

In an era where sustainability is a growing concern, ACE stands out for its commitment to environmentally responsible practices. The company incorporates recycled plastic materials into its extrusion processes when appropriate, helping clients reduce our environmental footprint without compromising on quality. This is particularly relevant for water treatment applications, where sustainability aligns with the industry’s mission to protect and preserve water resources.

ACE’s ability to repurpose recycled materials into high-quality tubing demonstrates our innovative approach to balancing performance and environmental responsibility. By offering sustainable options, ACE helps water treatment companies meet our sustainability goals while maintaining the durability and reliability required for critical applications.

5. Comprehensive Secondary Operations

Beyond extrusion, ACE offers a wide range of secondary operations to enhance the functionality of our water treatment tubing. These services include:

Beyond extrusion, ACE offers a wide range of secondary operations to enhance the functionality of our water treatment tubing. These services include:

- Custom Color Matching: ACE can produce tubing in a full spectrum of colors, ensuring compatibility with branding or system identification requirements.

- Labeling and UPC Application: Clear, scannable labeling is essential for inventory management and regulatory compliance in water treatment systems. ACE’s precise printing capabilities ensure that labels and UPC codes are easily readable and durable.

- Cutting and Fabrication: ACE provides cut-to-length, coiled, or spooled tubing, as well as drilling, punching, and notching services, to meet the specific needs of water treatment equipment.

- Packaging Solutions: ACE offers customized packaging to protect tubing during shipping and storage, ensuring it arrives in pristine condition.

These value-added services simplify the supply chain for water treatment companies, allowing them to focus on our core operations while ACE handles the intricacies of tubing production and finishing.

6. Global Reach and Personalized Service

With a network spanning the United States, Canada, Mexico, and Europe, ACE is well-positioned to serve water treatment companies on a global scale. Despite our extensive reach, ACE remains committed to providing personalized service, treating every client—whether a large corporation or a small business—with the same level of attention and care.

ACE’s team is known for its responsiveness, offering fast quotations, expert material recommendations, and prompt responses to inquiries. This customer-centric approach ensures that water treatment professionals receive the support they need to keep our projects on track and within budget.

Applications of ACE’s Water Treatment Tubing

ACE’s custom tubing is used in a wide range of water treatment applications, including:

- Filtration Systems: Tubing for reverse osmosis, ultrafiltration, and microfiltration systems, designed to withstand high pressures and chemical exposure.

- Chemical Dosing Systems: Non-toxic, chemical-resistant tubing for precise delivery of disinfectants and treatment chemicals.

- Water Distribution: Durable tubing for municipal and industrial water distribution systems, engineered to prevent leaks and ensure long-term performance.

- Wastewater Treatment: Tubing designed to handle corrosive fluids and harsh environmental conditions in wastewater treatment plants.

By offering tailored solutions for these and other applications, ACE helps water treatment professionals achieve optimal performance and reliability in our systems.

Why Choose ACE for Water Treatment Tubing?

Absolute Custom Extrusions, Inc. distinguishes itself as a superior supplier of water treatment tubing through its combination of customization, quality, innovation, and customer service. Our ability to deliver precision-engineered tubing that meets the exact specifications of water treatment applications sets them apart in a competitive industry. With a focus on sustainability, compliance with regulatory standards, and comprehensive secondary operations, ACE provides end-to-end solutions that simplify the procurement process and enhance system performance.

Whether you’re designing a new water treatment system or seeking to improve an existing one, ACE’s expertise, experience, and commitment to excellence make them the ideal partner. By choosing ACE, water treatment professionals can trust that they are receiving tubing that is not only high-quality and reliable but also tailored to our client’s unique needs.